Whether you're driving a traditional gas-powered car or cruising in an electric vehicle, battery health remains a crucial part of keeping your ride running smoothly. While these vehicles use vastly different battery technologies, both can face challenges like corrosion - a common issue that can sneak up on any car owner and impact their vehicle's performance.

What is Car Battery Corrosion?

Car battery corrosion is a buildup of white or green crystals on the battery terminals, caused by the interaction of the battery acid with the metal terminals. The battery acid is a mixture of sulfuric acid and water, and it interacts with the metal terminals over time to produce hydrogen gas and sulfate crystals. These crystals form a white or green coating on the terminals, known as corrosion. Corrosion can be accelerated by dirt, grime, and moisture. Dirt and grime can provide an ideal environment for corrosion to develop, and moisture can dissolve the sulfate crystals, allowing them to spread and cover a larger area of the terminals.

What Problems Can Car Battery Corrosion Cause?

Car battery corrosion, the buildup of white or green crystals on the battery terminals, is a common issue that can lead to a variety of problems if left unchecked. These crystals, formed by the interaction of battery acid and metal terminals, can hinder the flow of electrical current, causing a range of issues that can affect your vehicle's performance and safety.

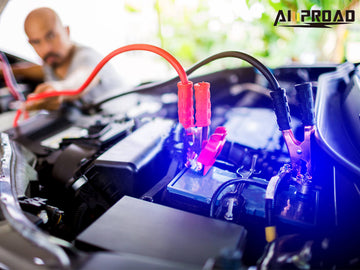

One of the primary concerns with car battery corrosion is its impact on starting power. The corrosion acts as a barrier, obstructing the smooth transfer of electricity from the battery to the starter motor, making it difficult for the engine to crank and start. Frequent jump starter or a prolonged struggle to start the car can be a telltale sign of corrosion interfering with the battery's ability to deliver sufficient power.

Apart from starting problems, corrosion can also affect the electrical systems throughout the vehicle. The reduced current flow can lead to erratic behavior of various components, such as lights, wipers, and power windows. The electrical instability can also cause malfunctions in sensors and control modules, potentially triggering warning lights or disrupting vehicle functions.

Furthermore, car battery corrosion can pose a safety hazard. The buildup of crystals can increase electrical resistance, leading to overheating and potential damage to the battery cables and terminals. In extreme cases, severe corrosion can cause sparks or even small explosions if the clamps touch each other, posing a fire risk.

In addition to the immediate concerns, car battery corrosion can also contribute to premature battery failure. The constant interference with current flow and the buildup of crystals can accelerate the battery's deterioration, shortening its lifespan and requiring more frequent replacements. This can lead to additional costs and inconvenience.

To prevent these issues and maintain the health of your car's electrical system, it is crucial to regularly inspect the battery terminals for signs of corrosion. If corrosion is detected, prompt cleaning with a baking soda and water solution or a commercial battery terminal cleaner is necessary to remove the buildup and restore proper electrical conductivity.

How to Clean Car Battery Corrosion

Knowing how to clean car battery corrosion is as important as knowing how to boost a car with a jump starter, the unsightly buildup of white or green crystals on the battery terminals, is a significant concern for vehicle owners. This accumulation of corrosion can hinder the flow of electricity, leading to starting problems, erratic electrical behavior, and even potential safety hazards. Fortunately, with proper care and attention, you can effectively eliminate car battery corrosion and safeguard your vehicle's electrical health.

Preparation and Positioning

Before embarking on the cleaning process, ensure the vehicle is parked in a well-ventilated area, away from flammable materials or sparks. Engage the parking brake and turn off the ignition to prevent accidental starting.

Locate the positive (+) and negative (-) battery terminals. The positive terminal is typically marked with a "P" or "+" symbol, while the negative terminal is marked with an "N" or "-" symbol.

Wearing a pair of insulated and non-conductive gloves, carefully loosen the negative battery cable clamp using a wrench or pliers. Disconnect the cable from the negative terminal and set it aside, ensuring it does not touch the positive terminal or any metal surfaces.

Remove protective covers from the battery terminals if applicable, to expose them for thorough cleaning.

Neutralizing Corrosion and Cleaning

Prepare a baking soda solution by mixing one tablespoon of baking soda with one cup of distilled water in a small container. The solution should fizz and bubble as the baking soda dissolves.

Using a brush or a clean rag, generously apply the baking soda solution or a commercial battery terminal cleaner to both the positive and negative terminals. Allow the solution to sit for a few minutes to neutralize the battery booster acid.

With a wire brush, gently scrub the terminals to remove the loosened corrosion and any remaining buildup. Be careful not to damage the terminal surfaces. Pay particular attention to areas where the corrosion is most severe.

For deep-seated corrosion in crevices and corners, use an old toothbrush dipped in the baking soda solution or cleaner to thoroughly clean these areas.

Rinsing and Drying

Once the corrosion has been removed, thoroughly rinse the terminals with distilled water to remove any remaining baking soda residue or cleaner.

Using a clean rag or paper towel, pat the terminals dry to remove any excess water. Ensure the terminals are completely dry before proceeding to the next step.

Protective Coating

To protect the clean terminals from moisture ingress and further corrosion, apply a thin layer of petroleum jelly or dielectric grease to each terminal using a clean rag or paper towel.

Spread the grease evenly over the entire surface of the terminals, ensuring they are well coated.

Preventing Future Corrosion

To prevent future corrosion, regularly inspect the battery terminals for signs of corrosion and clean them if necessary.

Keep the battery terminals clean and free of debris.

Apply a thin layer of petroleum jelly or dielectric grease to the terminals after cleaning to protect them from moisture and corrosion.

Seek Professional Help if Needed

If you are unsure about any of the steps involved in cleaning car battery corrosion, or if the corrosion is severe, it is always best to consult with a qualified mechanic for assistance.

Navigating the intricacies of electric vehicle (EV) battery maintenance can be a daunting task for those unfamiliar with the specialized techniques and equipment involved. If you find yourself hesitant to tackle the cleaning of car battery corrosion on your own, or if the corrosion appears particularly severe, seeking expert assistance from a qualified mechanic is always the most prudent course of action.

Amproad, a leading supplier of Level 2 EV charger, strongly recommends consulting a certified mechanic for any EV battery maintenance concerns, particularly those involving corrosion. Their team of experienced technicians possesses the necessary expertise and tools to safely and effectively address even the most challenging corrosion issues.

When attempting to clean car battery corrosion on your own, it is crucial to prioritize safety by adhering to proper safety protocols, utilizing the appropriate protective gear, and employing the correct cleaning solutions. Failure to do so can lead to potential hazards, such as battery acid burns or electrical shocks.

Amproad emphasizes the importance of consulting a qualified mechanic for severe corrosion cases. These situations often require specialized techniques and equipment that may not be readily available to the average vehicle owner. Attempting to handle such cases without proper expertise can exacerbate the issue, potentially damaging the battery beyond repair.

By entrusting your EV battery maintenance needs to a qualified mechanic, you gain the assurance that your vehicle is in capable hands, ensuring optimal performance, extended battery lifespan, and enhanced safety. Amproad wholeheartedly supports this approach, encouraging EV owners to seek expert guidance whenever battery concerns arise.

Additional Tips for Electric Vehicle Battery Maintenance

Electric vehicles have revolutionized the automotive landscape, offering a cleaner and more sustainable mode of transportation. However, unlike traditional gasoline-powered vehicles, electric vehicles rely on batteries for their power source. As with any battery, proper care and maintenance are essential to ensure optimal performance and longevity. While regular cleaning of corrosion is crucial, there are additional measures you can take to safeguard your electric vehicle battery and extend its lifespan:

Temperature Monitoring: Safeguarding Against Thermal Extremes

Extreme temperatures, both scorching heat and frigid cold, can take a toll on your electric vehicle charging station. Excessive heat can accelerate the degradation process, while subzero temperatures can hinder the battery's ability to deliver optimal performance. To combat these environmental challenges, utilizing a battery management system or app is highly recommended. These tools provide real-time insights into the battery's temperature, allowing you to take proactive measures to protect it from extreme conditions. During hot summer days, consider parking your vehicle in a shaded area or using a sunshade to minimize heat exposure. Conversely, in frigid winter conditions, preheating the cabin while the vehicle is still plugged in can help alleviate the strain on the battery during initial operation.

Deep Discharges: A Threat to Battery Longevity

While electric vehicles offer impressive driving ranges, it's crucial to avoid draining the battery completely. Just as overcharging can damage the battery, deep discharges can also shorten its lifespan. Aim to maintain a battery level between 20% and 80% whenever possible. This practice not only prolongs the battery's health but also enhances its performance.

Compatible Chargers: Ensuring Optimal Energy Transfer

When it comes to charging your electric vehicle, using the appropriate charger is paramount. Each electric vehicle model has a recommended charger, designed specifically to deliver the correct voltage and amperage for safe and efficient charging. Using an incompatible charger can result in damage to the battery, leading to reduced performance and potential safety hazards. Always consult your vehicle's owner's manual or contact the manufacturer for the recommended charger type.